Used Equipment

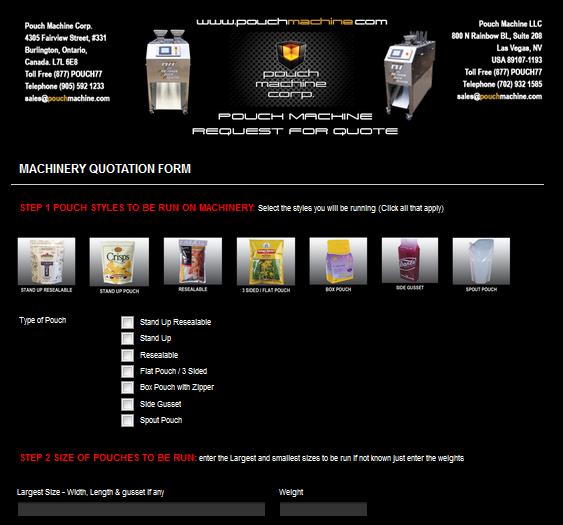

Quote

Whats New

Pouch Marking

Other equipment

Solutions

Videos

Co-Packer

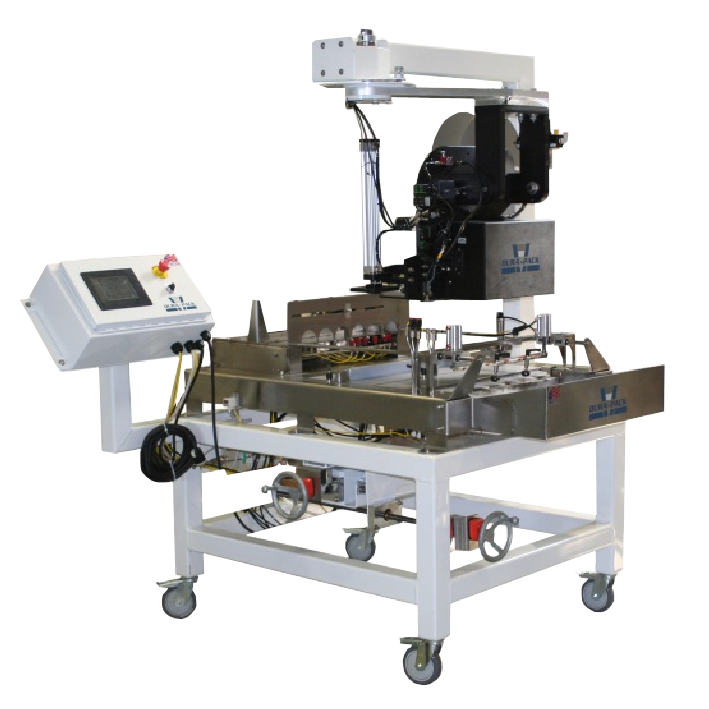

SPEEDS: Up to 40 (80) Pouches per minute

SIZES: from 3" (75mm) wide to 20" (500mm) wide

SIZES: from 3" (75mm) wide to 20" (500mm) wide

SPEEDS: Up to 20 (40) Pouches per minute

SIZES: from 4" (100mm) wide to 20" (500mm) wide

SIZES: from 4" (100mm) wide to 20" (500mm) wide

WITH INTERGRATED PUMPS

FROZEN ALCOHOL BEVERAGES

WINE COOLERS

OILS

CHEMICALS

KETCHUP

HONEY

WATER

AUTOMOTIVE

SOAPS

DETERGENTS

JUICES

WINE COOLERS

OILS

CHEMICALS

KETCHUP

HONEY

WATER

AUTOMOTIVE

SOAPS

DETERGENTS

JUICES

PERFECT FOR

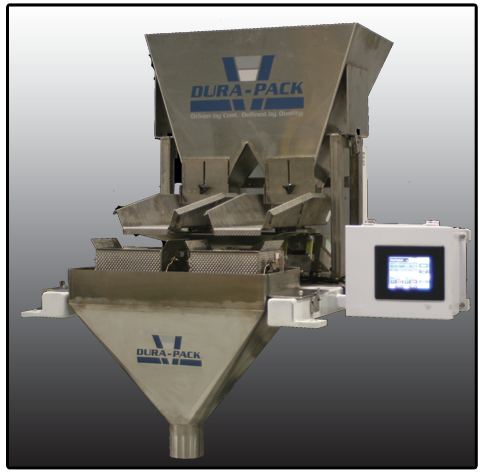

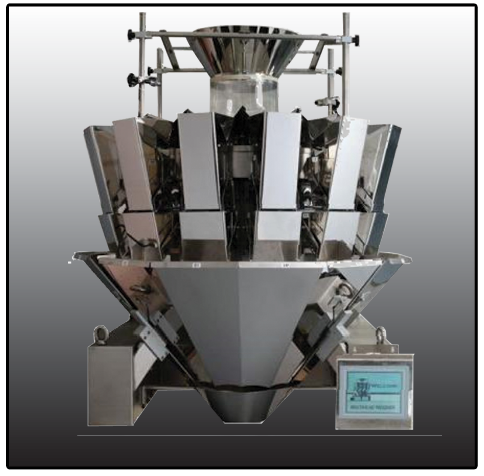

WITH INTERGRATED SCALE

PERFECT FOR

FREE FLOWING PORODUCTS

POWDERS

COFFEE & TEA

SUGAR

CEREAL

SEED

NUTS

CANDY

PASTA

PET FOOD

RICE

POWDERS

COFFEE & TEA

SUGAR

CEREAL

SEED

NUTS

CANDY

PASTA

PET FOOD

RICE

POUCH MACHINERY

With our “Made in the Canada" M7 as the flagship and 10 years of ingenuity in multiple markets, the M7 has evolved to meet our customer's needs of "low maintenance" and "maximum up time". Our line of pouch machines allow you to move away from costly, labor-intensive manual packing to a world of affordable high-speed automation. Capable of interfacing with a multitude of fillers and designed to be simple to use with a small footprint.

7 MODELS - with 100's of Combinations

SPEEDS of up to 20,40,60,80 BPM

COMMON TO ALL MODELS

AVAILABLE IN 7 LANGUAGES.

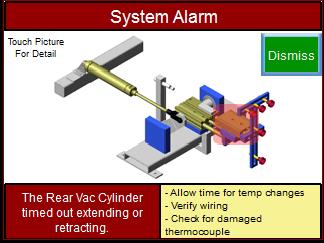

Troubleshooting is made simple

with our state of the art 3D Alarm

system. Should and error occur

the M7 Will stall and the alarm

screen will appear giving the

operator the exact location of the

problem. With the "Sensor

Overide" they can override the

sensor and carry on production

until maintenace has time to

change it.

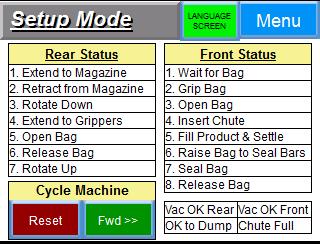

Recipe Selection

Have Multiple jobs to run? No

problem store each on for

easy recall and fast

changeover.

3D System Alarms with Sensor Override

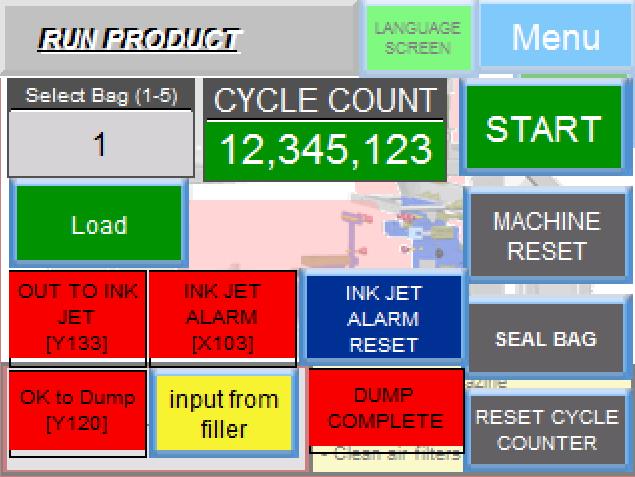

With the M7 Touch Screen

control, take a leap to making set

up, operation, troubleshooting &

recipes as easy as using your

smart phone. Think of it as having

a factory trained technician at

your beck and call, it is always

monitoring & fine tuning for you.

Since staff responsibilities differ

the M7 has 3 levels of security.

· Economical

· Small footprint

· Simple to operate

· Load pouches while running

· Low operating costs

· Low maintenance costs

· Fast bag size change

· Heavy Duty Stainless Steel Frame, Panels & Contact Parts

· Automatic Bag Opening and Placing System

· Twin, Individually Controlled Sealing Jaws

· Quick Bag Size Change

· Bag In Place Detection “ NO BAG NO DUMP”

· Adjustable Leveling Feet and Casters

· Simple “Plug In” Interface with Filler

· PLC Controlled

· Start Up Kit - Cables, Manuals etc

· National Brand Pneumatics, Electronics, Bearings and Motors

· Twin Digital Temperature Controls

· 1-Year Limited Warranty

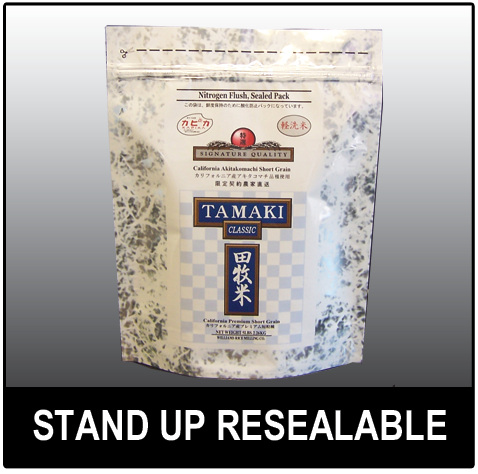

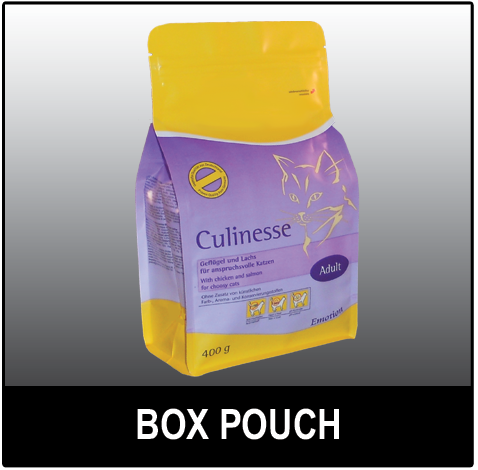

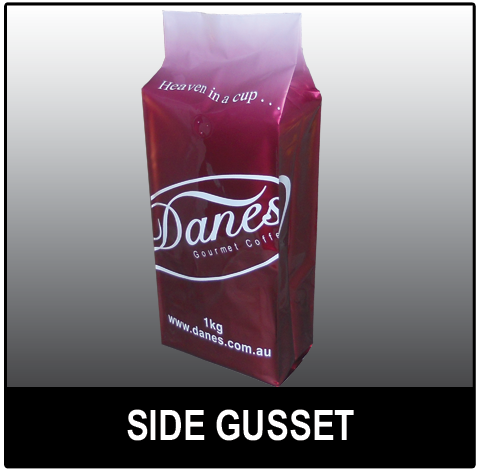

The M7 Pouch Machines have the versatility to work with many different styles of pre-made pouches.

POUCH LOADING

The process starts with up to 300 empty pouches being placed into the adjustable cartridge. Bags can be loaded while the machine is in operation.

POUCH FILLING

SEALING

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators. They are rotated to the fill area and opened. Multiple bag detection switches are used at various points in the cycle to ensure correct bag placement and full bag opening. Should a reject bag be detected it is ejected from the machine and the process continues. Rejected bags can be inspected by the operator and re-used if good.

Product enters the transition chute while the bag is being opened below. Upon pouch detection the chute enters the bag and opens its gates. Product is dispensed immediately, without spillage and protecting the seal from contamination. Difficult product that easily bridges is dispensed into the pouch directly from the filler, through the “open gate”.During filling, pouches are held in place with our “posi-hold” gripper system. This allows for heavy weights and shock loads without disturbing bag position. Once filled the pouch is pulled tight for sealing

POUCH OPENING

Digitally controlled, the ribbed or flat constant heat seal bars give a integral attractive seal. Pouches are sealed “in place” eliminating wrinkles, folded corners and non aligned seals. Impulse sealing is also available.

Our quick adjustment system makes

work much easier and allows you to save

time. It enables you to change bag sizes

in a matter of minutes and to reproduce

this setting whenever needed. This is the

perfect solution when you have multiple

pouches to run Save Recipes on the

touch screen.

Low single phase voltage, compressed

air, locking adjustable height casters and

quick release interface plugs. The M7’s

can quickly be moved to different lines or

for cleaning.

PORTABILITY

ADJUSTMENT

© All content on the www.pouchmachine.com siite is copyright protected property. All rights reserved.